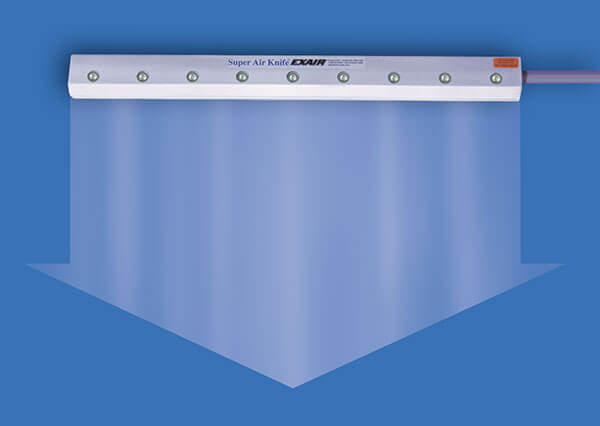

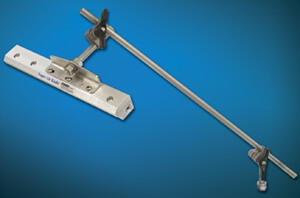

Super Air Knife™ – Quiet, hard-hitting curtain of air for blowoff, cleaning, drying and cooling.

What is the Super Air Knife?

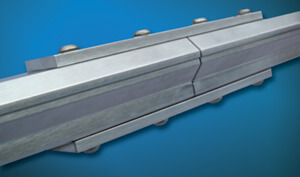

The Super Air Knife is the latest generation of air knife that dramatically reduces compressed air usage and noise when compared to other blowoffs. The Super Air Knife offers a more efficient way to clean, dry or cool parts, webs or conveyors. It delivers a uniform sheet of laminar airflow across the entire length with hard-hitting force.

Noisy blowoffs become a whisper when replaced with the compact Super Air Knife. Even at high pressures of 80 PSIG (5.5 BAR), the sound level is surprisingly quiet at 69 dBA for most applications! Amplification ratios (entrained air to compressed air) of 40:1 are produced. The Super Air Knife meets OSHA dead-ended pressure and noise requirements.

Specials are available. Please contact us.

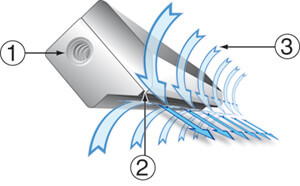

How the Super Air Knife works

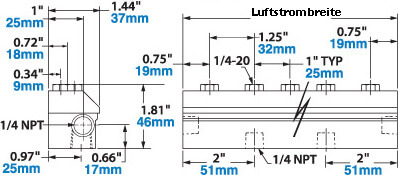

Compressed air flows through an inlet (1) into the plenum chamber of the Super Air Knife. The flow is directed to a precise, slotted orifice. As the primary airflow exits the thin slotted nozzle (2), it follows a flat surface that directs the airflow in a perfectly straight line. This creates a uniform sheet of air across the entire length of the Super Air Knife. Velocity loss is minimized and force is maximized as the room air (3) is entrained into the primary airstream at a ratio of 40:1. The result is a well defined sheet of laminar airflow with hard-hitting force and minimal wind shear.

Applications

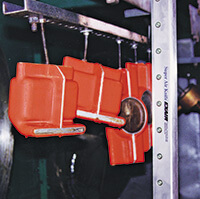

- Part drying after wash

- Sheet cleaning in strip mills

- Conveyor cleaning

- Part or component cooling

- Web drying or cleaning

- Environmental separation

- Pre-paint blowoff

- Bag opening/filling operations

- Scrap removal on converting operations

Dry

Blowoff

Cool

PVDF (Polyvinylidene Fluoride) Super Air Knife

Super Air Knives in PVDF (Polyvinylidene Fluoride) offers superior strength and are resistant to UV-light, inorganic chemicals, solvents, ozone, weather, fungi, chlorinated hydrocarbons, highly corrosive acids, weak bases and salts. The PVDF Super Air Knife uses PTFE Shims, Type 316 Stainless Steel pipe plugs, and Hastelloy c-276 alloy screws to withstand harsh environments. The PVDF Super Air Knife is suitable for manufacturing processes that involve electroplating, solar cells, lithium ion batteries, transfer of acids and caustic chemicals, brine, solvent recovery, semiconductors, and medical devices. It can withstand temperatures up to 275oF (135oC).

FAQ’s

[fusion_faq filters=”no” number_posts=”-1″ post_status=”” cats_slug=”questions-about-air-curtains” exclude_cats=”” orderby=”date” order=”ASC” featured_image=”” type=”” inactive_icon=”” active_icon=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” boxed_mode=”” border_size=”” border_color=”” hue=”” saturation=”” lightness=”” alpha=”” background_color=”” hover_color=”” divider_line=”” divider_color=”” divider_hover_color=”” fusion_font_family_title_font=”” fusion_font_variant_title_font=”” title_font_size=”” title_line_height=”” title_letter_spacing=”” title_text_transform=”” title_color=”#023580″ icon_size=”” icon_color=”” icon_boxed_mode=”” icon_box_color=”” icon_alignment=”” fusion_font_family_content_font=”” fusion_font_variant_content_font=”” content_font_size=”” content_line_height=”” content_letter_spacing=”” content_text_transform=”” content_color=”#7b838b” toggle_hover_accent_color=”” toggle_active_accent_color=”” /]