Full-Flow Air Knife™ – This low cost choice provides a curtain of air for blowoff, cleaning, drying and cooling.

What is the Full-Flow Air Knife?

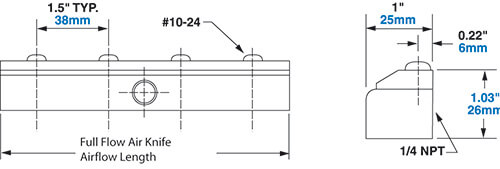

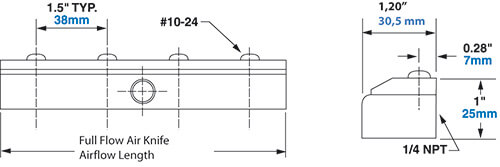

EXAIR’s Full-Flow Air Knife is an effective way to clean, dry or cool parts, webs or conveyors. It utilizes the coanda effect to pull in large volumes of surrounding air, producing a high flow, high velocity curtain of air. The “Full-Flow” provides airflow across the entire length. A 12″ (305mm) Full-Flow Air Knife measures 12″ (305mm). It has the compressed air inlet(s) on the rear. Inlets are available on each end at a small additional charge but are not recommended when uniform airflow is required.

Specials are available. Please contact us!

FAQ’s

[fusion_faq filters=”no” number_posts=”-1″ post_status=”” cats_slug=”questions-about-air-curtains” exclude_cats=”” orderby=”date” order=”ASC” featured_image=”” type=”” inactive_icon=”” active_icon=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” boxed_mode=”” border_size=”” border_color=”” hue=”” saturation=”” lightness=”” alpha=”” background_color=”” hover_color=”” divider_line=”” divider_color=”” divider_hover_color=”” fusion_font_family_title_font=”” fusion_font_variant_title_font=”” title_font_size=”” title_line_height=”” title_letter_spacing=”” title_text_transform=”” title_color=”#023580″ icon_size=”” icon_color=”” icon_boxed_mode=”” icon_box_color=”” icon_alignment=”” fusion_font_family_content_font=”” fusion_font_variant_content_font=”” content_font_size=”” content_line_height=”” content_letter_spacing=”” content_text_transform=”” content_color=”#7b838b” toggle_hover_accent_color=”” toggle_active_accent_color=”” /]