Locate costly leaks in your compressed air system!

What is the Ultrasonic Leak Detector?

The robust and grip-proof Ultrasonic Leak Detector (ULD) is a hand-held, high quality instrument that can locate costly leaks in a compressed air system. A person using the ULD need only aim it in the direction of a suspected leak. When a leak is present, an audible tone can be heard with the use of the headphones, and the LED display will light. Testing the various unions, pipes, valves and fittings of a complete installation can be done quickly and effectively at distances up to 20′ (6.1m) away!

Why the Ultrasonic Leak Detector?

Plants that aren’t maintained can easily waste up to 30% of the compressor output through leaks that go undetected. Compressing air is an expensive operation. Saving the wasted compressed air reduces overall operating costs. In large plants, the cost of a small air leak may be insignificant, but many small leaks when located and repaired can amount to huge energy savings.

What is Ultrasound?

Ultrasonic sound is a range of sound that is above human hearing capacity. Most people can hear frequencies from 20 Hz to 20 kHz. Sound from 20 kHz to 100 kHz can not be heard and is called “ultrasonic”. The Model 9207 Ultrasonic Leak Detector converts ultrasonic sound emissions to a range that is audible to people. (The sound generated by the ULD is 32 times lower in frequency than the sound that is received.)

Find Costly Leaks with the Ultrasonic Leak Detector

In a plant where loud noise levels exist, it is very difficult to locate leaks by merely listening for them. Most plant noises are in the normal audible range of human hearing, while air escaping from a small orifice is ultrasonic. The ULD can be adjusted to filter out background noise using the three sensitivity settings of X1, X10 and X100 along with an “on/off” thumb wheel for fine sensitivity adjustment. The parabola or tubular extension (shown below) can also be attached to the ULD to mask out intense background noise. The ULD detects only the ultrasonic sounds that are generated.

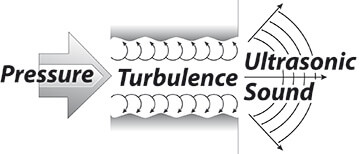

Ultrasound is directional in transmission and is loudest at the source. Turbulence created by the air forced through a small orifice generates ultrasonic sound. This emitted sound is called “white noise” and occurs when the air moves from a high pressure area such as a pipe or vessel and escapes to a low pressure area such as the room. The Ultrasonic Leak Detector converts the turbulent flow to a frequency that can be heard using the headphones. As the ULD moves closer to the leak, more LEDs on the display light to confirm the source of the leak.

In some cases, the suspected leak is in a hot area and/or close to moving parts. The tubular extension and parabola make it possible to probe these difficult locations from a distance to isolate the leak.

Find One Leak – Pay For Your Ultrasonic Leak Detector

Consider one small leak that is equivalent to a 1/16” diameter hole. At 80 PSIG, it consumes 3.8 SCFM (Standard Cubic Feet per Minute) or 108 SLPM (Standard Liters Per Minute).

Most large plants know their air cost. If you don’t know your actual cost per 1000 SCF (Standard Cubic Feet), a reasonable average is $0.25 per 1000 SCF (28,329 Standard Liters).

Dollars consumed per hour = SCFM consumed x 60 minutes x cost/1000 SCF

= 3.8 x 60 x 0.25/1000

= $0.06 per hour

= $1.37 per 24 hour period

= $9.58 per week

= $497.95 per year