Vortex Tubes: Cold air to -50°F (-46°C) from your compressed air supply – with no moving parts! Available in 3 sizes!

What Is A Vortex Tube?

A low cost, reliable, maintenance free solution to a variety of industrial spot cooling problems. Using an ordinary supply of compressed air as a power source, vortex tubes create two streams of air at the same time, one hot and one cold, with no moving parts. While the hot air is usually dissipated unused, the cold air flow is used in various manufacturing processes.

Even without moving parts and without electricity, the vortex tube mechanism always works reliably. Vortex nozzles are therefore a maintenance-free and cost-effective solution for a wide range of cooling tasks.

What are Vortex Tubes used for?

The classic field of application for Vortex Tubes is the cooling of weld seams, solder joints, components and workpieces (metal, plastic, wood, etc.).

It can also be used to protect tools from excessive heat development when machining, milling, drilling or turning. Our Vortex Tubes achieve:

- Temperatures from -50° to +260°F (-46° to +127°C)

- Flow rates from 1 to 150 SCFM (28 to 4248 SLPM)

- Refrigeration up to 10,200 Btu/hr. (2571 Kcal/hr.)

Temperatures, flows and refrigeration are adjustable over a wide range using the control valve on the hot end exhaust.

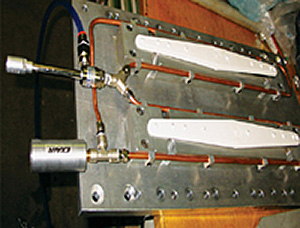

A Model 3225 Vortex Tube keeps plastic

dishwasher arms cool during ultrasonic

welding.

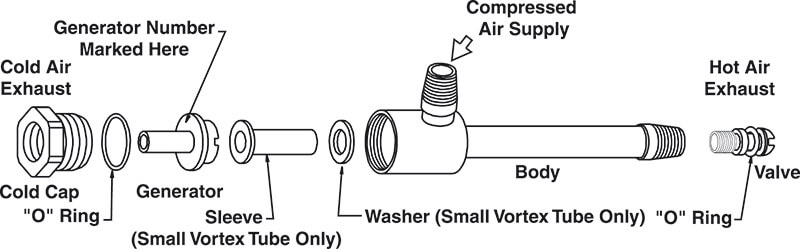

How does the Vortex Tube works?

Compressed air, normally 80-100 PSIG (5.5 – 6.9 BAR), is ejected tangentially through a generator into the vortex spin chamber. At up to 1,000,000 RPM, this air stream revolves toward the hot end where some escapes through the control valve. The remaining air, still spinning, is forced back through the center of this outer vortex. The inner stream gives off kinetic energy in the form of heat to the outer stream and exits the vortex tube as cold air. The outer stream exits the opposite end as hot air.

Why EXAIR Vortex Tubes?

EXAIR Vortex Tubes are constructed of stainless steel. The wear resistance of stainless steel, as well as its resistance to corrosion and oxidation, assures that EXAIR Vortex Tubes will provide years of reliable, maintenance-free operation.

Controlling Temperature and Flow in a Vortex Tube

Cold airflow and temperature are easily controlled by adjusting the slotted valve in the hot air outlet. Opening the valve reduces the cold airflow and the cold air temperature. Closing the valve increases the cold airflow and the cold air temperature. The percentage of air directed to the cold outlet of the vortex tube is called the “cold fraction”. In most applications, a cold fraction of 80% produces a combination of cold flow rate and temperature drop that maximizes refrigeration, or Btu/hr. (Kcal/hr.) output of a vortex tube. While low cold fractions (less than 50%) produce lowest temperatures, cold airflow rate is sacrificed to achieve them.

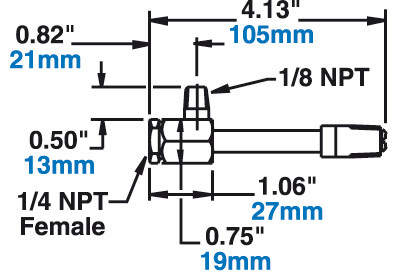

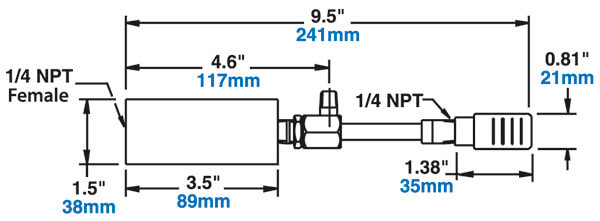

Most industrial applications, i.e., process cooling, part cooling, chamber cooling, require maximum refrigeration and utilize the 3200 series Vortex Tube. Certain “cryogenic” applications, i.e., cooling lab samples, circuit testing, are best served by the 3400 series Vortex Tube.

Setting a vortex tube is easy. Simply insert a thermometer in the cold air exhaust and set the temperature by adjusting the valve at the hot end. Maximum refrigeration (80% cold fraction) is achieved when cold air temperature is 50°F (28°C) below compressed air temperature.

Other Factors

Back Pressure:

The performance of a vortex tube deteriorates with back pressure on the cold air exhaust. Low back pressure, up to 2 PSIG (.1 BAR), will not change performance. 5 PSIG (.3 BAR) will change performance by approximately 5°F (2.8°C).

Filtration:

The use of clean air is essential, and filtration of 25 microns or less is recommended. EXAIR filters contain a five micron element and are properly sized for flow.

Inlet Air Temperature:

A vortex tube provides a temperature drop from supply air temperature (see Performance Charts above). Elevated inlet temperatures will produce a corresponding rise in cold air temperatures.

Noise Muffling:

EXAIR offers mufflers for both the hot and cold air discharge. Normally, muffling is not required if the cold air is ducted

Regulation:

For best performance, use line pressures of 80 to 110 PSIG (5.5 to 7.6 BAR). Maximum pressure rating is 250 PSIG (17.2 BAR), minimum 20 PSIG (1.4 BAR).

If you are unsure of your flow and temperature requirements, we recommend the purchase of an EXAIR Cooling Kit. It contains a vortex tube, cold air muffler, air line filter and all generators required to experiment with the full range of airflows and temperatures.