Standard Air Wipe™ – This hard-hitting 360° ring of airflow is the economical way to blowoff, dry, clean and cool.

We recommend our Super Air Wipe for higher temperatures and special requirements.

What Is The Standard Air Wipe?

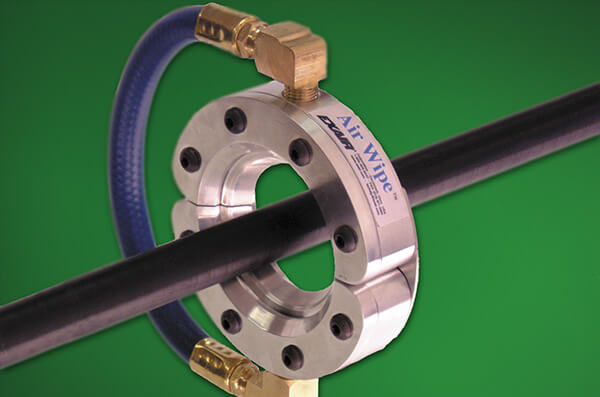

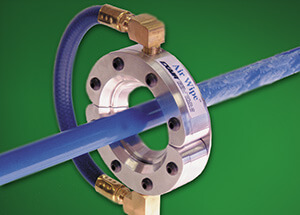

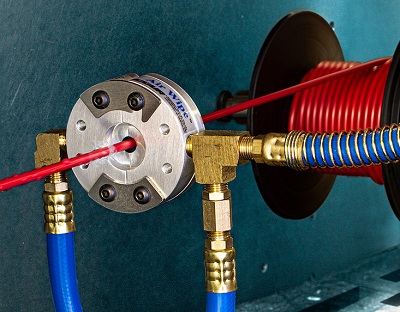

The Standard Air Wipe is a circular nozzle that provides a uniform 360° airstream. This air wipe is ideal for blowoff, drying, cleaning and cooling of pipe, cable, extruded shapes, hose, wire and more. The split design offers easy clamping around the surface of the material moving through it, eliminating the need for threading.

Why The Standard Air Wipe?

The Standard Air Wipe is the economical way concerning simple requirements under normal industrial environment. We recommend our Super Air Wipe for higher temperatures and special requirements.

Prior to the introduction of the Standard Air Wipe, the only way to blowoff, dry, clean and cool these surfaces was to use a ring of air nozzles. The high air consumption and noise levels of the nozzles along with inconsistent air velocity often delivered poor results. The Standard Air Wipe provides a high volume, high velocity airflow that is uniformly ejected from the 360° of its inner diameter. Velocity can be varied from a “blast” to a “breeze”. Air consumption and noise are low.

Standard Air Wipe Specifications

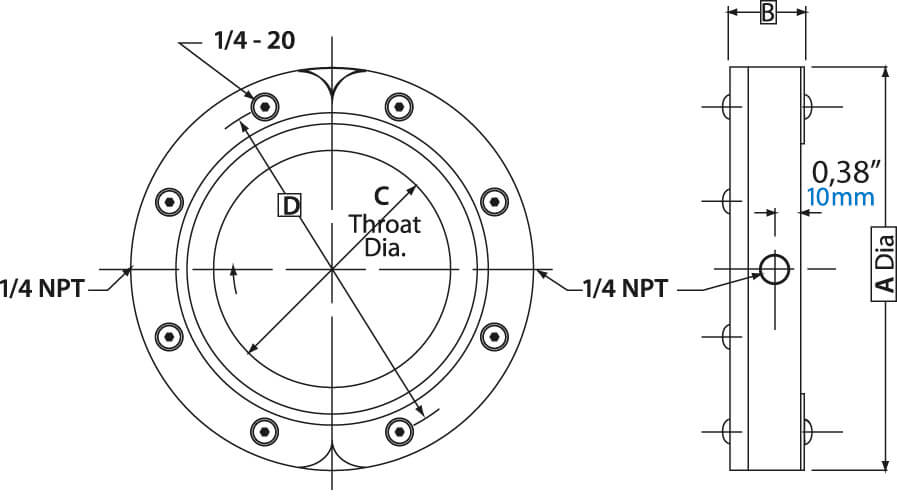

The Standard Air Wipe is available with different throat diameters (see below models)

Compressed Air Inlets: The Standard Air Wipe has compressed air inlets on each half. General purpose compressed air hose is supplied with sizes up to 4″ (102mm) that couples the air supply of one half to the other. Sizes 5″ (127mm) and larger have two inlets on each half that must be supplied with compressed air to maintain uniform airflow.

Temperature: The Standard Air Wipe is rated for temperatures up to 150°F (66°C).

Mounting: The Standard Air Wipe can be supported by the compressed air supply pipe. Tapped holes (1/4-20) on the bottom of the Standard Air Wipe can also be used for mounting.

Shim Sets: The Standard Air Wipe has a .002″ (.05mm) gap setting. The compressed air exhausts through a gap which is set with a plastic shim positioned between the cap and body of the Standard Air Wipe. Force and flow through the Standard Air Wipe may be easily increased by adding shims to open the gap. Shim-Sets include (1) .001″ (0.03mm), .003″ (0.08mm) and .004″ (0.10mm) thin plastic shims, available as accessories.

How The Standard Air Wipe Works

Compressed air flows through an inlet (1) of the Standard Air Wipe into an annular chamber (2). It is then throttled through a small ring nozzle (3) at high velocity. This primary airstream adheres to the coanda profile (4), which directs it down the angled surface of the Standard Air Wipe. A low pressure area is created at the center (5) inducing a high volume flow of surrounding air into the primary airstream. As the airflow leaves the Standard Air Wipe, it creates a conical 360° ring of air that attaches itself to the surface of the material running through it (6), uniformly wiping the entire surface with the high velocity airflow.