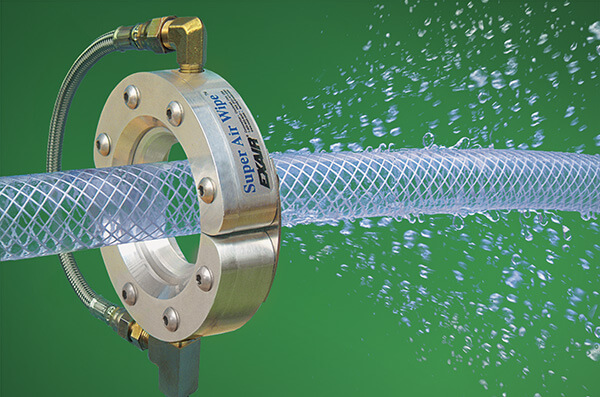

Super Air Wipe™ – Blowoff, dry, clean and cool pipe, cable, extruded shapes, hose, and wire

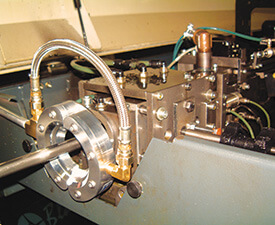

Split design requires no threading!

- Uniform 360° Air Flow

- For Environments Up To 800°F (427°C)

- Variable Force and Flow!

- Aluminum-body, Stainless Steel screws, Stainless Steel shims!

- Stainless Steel wire braided hose on sizes up to 4″ (102mm)!

- Full Stainless Steel models are available!

What is the Super Air Wipe?

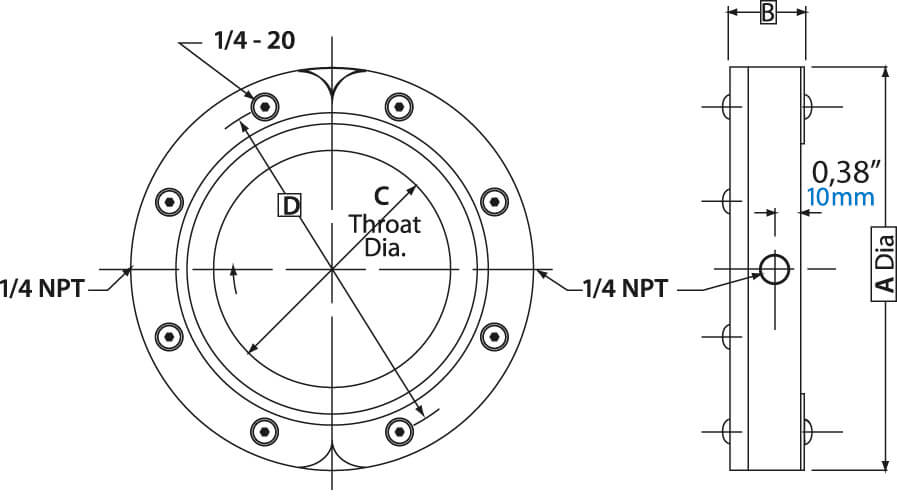

The offered Super Air Wipe is a high quality, corrosion-and heat-resistant model range for highest requirements. The Super Air Wipe provides a uniform 360° airstream that is ideal for blowoff, drying, cleaning and cooling of pipe, cable, extruded shapes, hose, wire and more. The split design of our air wipes offers easy clamping around the surface of the material moving through it, eliminating the need for threading. All models include stainless steel screws and shims. Stainless steel wire braided hose is also included on sizes up to 4″ (102mm) for added corrosion and heat resistance. Aluminum models are rated for temperatures up to 400°F (204°C) and stainless steel models for temperatures up to 800°F (427°C).

Why The Super Air Wipe?

Prior to the introduction of the Super Air Wipe, the only way to blowoff, dry, clean and cool cylindrical, round, or extruded surfaces was to use a ring of air nozzles. The high air consumption and noise levels of the nozzles along with inconsistent air velocity often delivered poor results. The Super Air Wipe (similar to the construction of Exair Super Air Knife) provides a high volume, high velocity airflow that is uniformly ejected from the 360° of its inner diameter. The airstream attaches itself to the material running through it to effectively wipe, clean or dry surfaces. Velocity can be varied from a “blast” to a “breeze”. Air consumption and noise are low.

How The Super Air Wipe Works

Compressed air flows through an inlet (1) of the Super Air Wipe into an annular chamber (2). It is then throttled through a small ring nozzle (3) at high velocity. This primary airstream adheres to the coanda profile (4), which directs it down the angled surface of the Super Air Wipe. A low pressure area is created at the center (5) inducing a high volume flow of surrounding air into the primary airstream. As the airflow leaves the Super Air Wipe, it creates a conical 360° ring of air that attaches itself to the surface of the material running through it (6), uniformly wiping the entire surface with the high velocity airflow.