What Are Atomizing Nozzles?

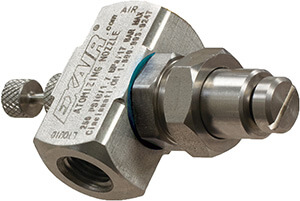

EXAIR´s Atomizing Spray Nozzles atomize fluids (most commonly water) in a range of spray patterns for a variety of uses. They combine liquid and compressed air to create a mist of atomized liquid that can be easily adjusted to meet the needs of your application. All models use stainless steel construction for durability and corrosion resistance. It should be noted that both media must always be under pressure!

Why Atomizing Nozzles?

With Atomizing nozzles, you can coat, cool, treat and paint a variety of products. Used with water, they are an efficient way to cool hot items in your automated process. These nozzles are also an excellent choice for dust migration.

Internal Mix Narrow Angle Round Pattern

These nozzles are excellent for spraying a concentrated mist of liquid.

Eleven models are available.

Internal Mix Wide Angle Round Pattern

These internal mix wide angle round pattern atomizing nozzles are great for covering a broad area.

Seven models are available.

Internal Mix Flat Fan Pattern

These atomizing nozzles are especially good for vertical or horizontal assembly lines, their broad thin pattern makes efficient use of your expensive liquids.

Seven models are available.

Internal Mix Deflected Flat Fan Pattern

This nozzle is designed for applications where space is at a premium. The flat fan pattern sprays at a right angle to the nozzle´s orientation, allowing spray to be placed precisely where it´s needed in close quarters.

One model is available.

Internal Mix 360° Hollow Circular Pattern

These nozzles are designed for applications where the spray pattern must be oriented away from the nozzle in all directions. 360° nozzles are ideal where a smooth, even coating is needed on the ID of pipe or similar ductwork.

Two models are available.

With EXAIR´s atomizing nozzles, you can coat, cool, treat and paint a variety of products. Used with water, they are an efficient way to cool hot items in your automated process. These nozzles are also an excellent choice for dust migration.

Sound levels for the individual Atomizing Spray Nozzles are not provided. The fluid, pressure, surfaces being treated and surrounding enclosures used in conjunction with the Atomizing Spray Nozzle to form the system will determine the acutal sound levels (which can vary greatly). Max temperature is 400°F (204°C) for Atomizing Spray Nozzles. All atomizing nozzles are CE compliant.