What are Air Nozzles and Jets?

We offer a complete selection of air nozzles and Jets suited to a wide range of blowoff, cooling and drying applications. These air nozzles have been engineered to provide a strong blast of airflow while minimizing air consumption and noise levels. They are available in many configurations and materials to suit the requirements of your application.

Selecting the Right Air Nozzle

EXAIR manufactures a wide selection of Air Nozzles and Jets, which are divided into two groups. The first group includes Air Nozzles and Jets that deliver force up to 22 ounces (624 grams), making them suitable for most blowoff, drying and cooling applications. The second group includes Air Nozzles that produce high force up to 23 pounds (10.43 kg) where additional reach and force are required.

- Brass general purpose applications. Max temp 400oF (204oC)

- Zinc aluminum alloy general purpose applications. Max temp 250oF (121oC)

- Type 303 Stainless Steel high temperatures and corrosive environments. Max temp 800oF (426oC)

- Type 316 Stainless Steel high temperatures, corrosive environments, and mechanical wear. Max temp 1000oF (538oC)

- PEEK replaces metals in harsh environments. Offers chemical resistance, non-marring. Max temp 320oF (160oC)

Click a product category to find out more!

Model 1108 Atto Super Air Nozzle

2.0 Ozs of Force

2.5 SCFM (71 SLPM)

316 Stainless Steel, Plastic (PEEK)

Model 1109 Pico Super Air Nozzle

5.0 Ozs of Force

4.9 SCFM (139 SLPM)

316 Stainless Steel, Plastic (PEEK)

Model 1110 Nano Super Air Nozzle

8.1 Ozs of Force

8.3 SCFM (235 SLPM)

316 Stainless Steel, Plastic (PEEK)

Model 1010SS Micro Air Nozzle

12 Ozs of Force

13 SCFM (368 SLPM)

303 Stainless Steel

Model 1102, 1103 Mini Super Air Nozzles

9 Ozs of Force

10 SCFM (396 SLPM)

Zinc/Aluminum, 316 Stainless Steel

Model 1100, 1101 Super Air Nozzles

13 Ozs of Force

14 SCFM (396 SLPM)

Zinc/Aluminum, 316 Stainless Steel, Plastic (PEEK)

Model 1001, 1002 and 1003 Safety Air Nozzles

9 to 18 Ozs of Force

10 to 18 SCFM

(283 to 509 SLPM)

Brass, 303 Stainless Steel

Model 1009 Adjustable Air Nozzle

12 Ozs of Force

13 SCFM (368 SLPM)

Aluminum, 303 Stainless Steel

Model 1122 2″ Flat Super Air Nozzle

22 Ozs of Force

22 SCFM (622 SLPM)

Zinc/Aluminum, 316 Stainless Steel

Model 1126 1″ Flat Super Air Nozzle

9.8 Ozs of Force

10.5 SCFM (297 SLPM)

Zinc/Aluminum, 316 Stainless Steel

Model 1004SS, 1006SS, 1008SS Back Blow Nozzle

75/80/89/ dBA sound level

4.5/22/57 SCFM

316 Stainless Steel

Model 6013 / 6013SS High Velocity Air Jet (Venturi Nozzle)

20 Ozs of Force

22 SCFM (622 SLPM)

Brass, 303 Stainless Steel

Model 6019 / 6019SS Adjustable Air Jet (Venturi Nozzle)

16 Ozs of Force

18 SCFM (509 SLPM)

Brass, 303 Stainless Steel

High Force Air Nozzles

Some applications require extremely high force with extensive reach. EXAIR’s High Power Safety Air Nozzles, 2″ High Power Super Air Nozzles, Large Super Air Nozzles and Super Air Nozzle Clusters provide incredibly strong blowing force. They are ideal for part ejection as well as blowoff, cooling and drying applications. Now, EXAIR has engineered Large Super Air Nozzles that put the blowing capability of multiple nozzles into one single air nozzle. Hard-hitting force is measured in pounds, not ounces. All meet OSHA noise level and pressure requirements.

Click a product category to find out more!

Model HP1002 High Power Safety Air Nozzles

1.8 Lbs of Force

32 SCFM (906 SLPM)

Brass, 303 Stainless Steel

Modell HP1125 2″ High Power Flat Super Air Nozzle

2.5 Lbs of Force

37 SCFM (1039 SLPM)

Zinc/Aluminum, 316 Stainless Steel

Model HP1126 1″ High Power Flat Super Air Nozzle

462 Grams

17.5 SCFM (495 SLPM)

Zinc/Aluminum, 316 Stainless Steel

Model 1104 to 1121 Large Super Air Nozzle

1.9 to 23 Lbs of Force

35 to 300 SCFM (991 to 8495 SLPM)

Zinc/Aluminum, 316 Stainless Steel

Model 1111-4, 1111-7 and 1111-12 Super Air Nozzle Cluster

3.2 to 9.8 Lbs of Force

56 to 168 SCFM

(1585 to 4754 SLPM)

Zinc/Aluminum

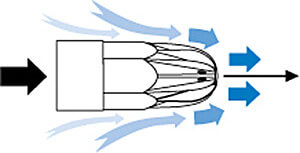

How Air Nozzles Work

Air Nozzles use the coanda effect to amplify compressed airflow 25 times or more. As illustrated on the right, compressed air (black arrows) is ejected through a series of nozzles on the outer perimeter. As the air travels along the outer wall of the nozzle, surrounding air (blue arrows) is entrained into the stream. The airstream that results is a high volume, high velocity blast of air at minimal consumption. The air is always ejected so it can vent safely, well below OSHA dead ended pressure requirements, should the nozzle end be blocked.

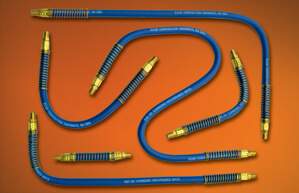

Adding Flexibility

For applications where frequent repositioning of the standard force Air Nozzles and Jets is required, the Flexible Stay Set HosesTM are ideal. Simply mount the hose in close proximity to the application and bend it to aim the airstream at the target. Since the hos has “memory”, it will not creep or bend. It always keeps the aim until physically moved to the next position.