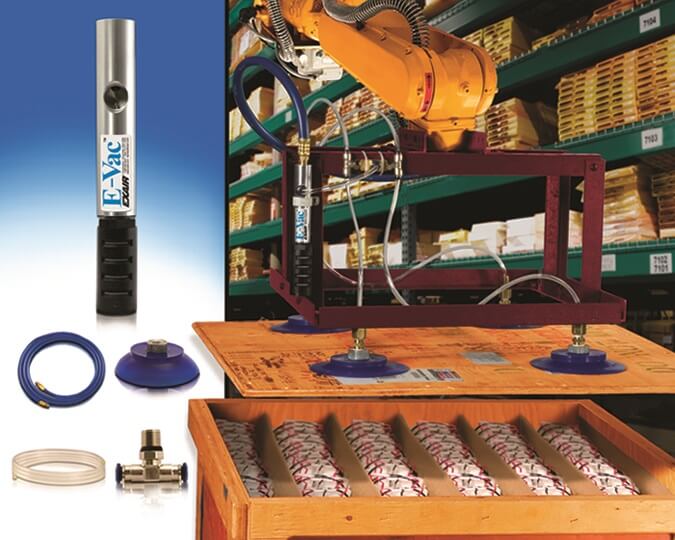

E-Vac® – Vacuum Generators – Vacuums for lifting, clamping, mounting and placement!

What Is The E-Vac?

The compressed air powered E-Vac single stage vacuum generators are the low cost way to create a vacuum for:

- Pick and place

- Clamping

- Lifting

- Chucking

- Alignment

- Surface mounting

- Vacuum forming

E-Vac compressed air powered vacuum pumps provide instantaneous response and are most commonly used for pick and place operations.

Why The E-Vac?

The E-Vac vacuum generators have been engineered for high efficiency to minimize air consumption. These single stage, all aluminum units provide consistent, steady vacuum, unlike mechanical vacuum pumps. Dust and small particulates easily pass through the vacuum generator and they have no moving parts, making them maintenance free.

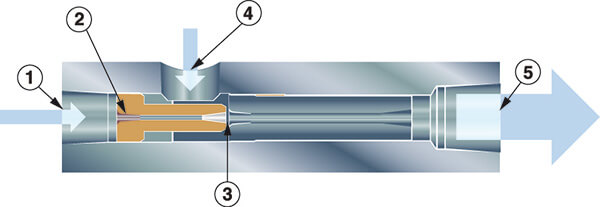

How The E-Vac Works

Compressed air flows through the inlet (1), then through a single directed nozzle (2). As the airstream exhausts, it expands and increases in velocity prior to passing through the venturi (3). A vacuum inlet tangential to the primary airflow (4) is located at the suction point between the orifice and the venturi. The airflow that is drawn through the vacuum inlet mixes with the primary airstream, then exhausts on the opposite end (5).

E-Vac Is Easy To Use

The E-Vac is available in two styles:

In-Line E-Vac Vacuum Generator

These single stage, cylindrical units are compact and easy to mount at the point of use. They can be held in playe by threading them directly onto a compressed air line or with the use of a mounting clip. There are 7 models available for with porous materials, like cardboard, with vacuum levels up to 21 inHg (71 kPa) and vacuum flows up tp 18.5 SCFM (524 SLPM). There 7 models available for use with non-porous materials such as glass, with vacuum levels up to 27 inHg (91 kPa) with vacuum flows up to 15.8 SCFM (447 SLPM).

Adjustable E-Vac Vacuum Generator

This series of vacuum generators permits easy adjustment by simply loosening the locknut and turning the exhaust to increase or decrease the level of vacuum and vacuum flow. This style is also an excellent choise where large particulate may be present and passed through the vacuum system. There are 4 models with adjustable vacuum up to 25 inHg (85 kPa) and vacuum flow up to 81 SCFM (2,292 SLPM).