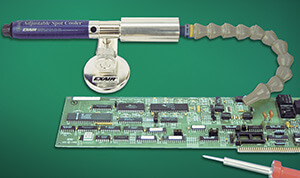

Adjustable Spot Cooler

With the turn of a knob, precise temperature settings to -30°F (-34°C) from your compressed air supply for spot cooling.

What is the Adjustable Spot Cooler?

A low cost, reliable, maintenance free solution to a variety of industrial spot cooling problems. With the turn of a knob, you can select the temperature best suited to your application. The Adjustable Spot Cooler provides a precise temperature setting from -30°F (-34°C) to room temperature.

The Adjustable Spot Cooler incorporates a vortex tube that converts an ordinary supply of compressed air into cold air. The Adjustable Spot Cooler can produce:

- Temperatures from -30° to +70°F (-34°C to 21°C)

- Parts included for flow rates from 15 to 30 SCFM (425 to 850 SLPM) – 25 SCFM

(708 SLPM) generator factory installed - Refrigeration up to 2000 Btu/hr. (504 Kcal/hr.)

Flexible tubing that holds its position directs the cold air. A swivel magnetic base provides

easy mounting and portability. No moving parts or CFC’s assures maintenance free operation.

Why The Adjustable Spot Cooler?

The Adjustable Spot Cooler is quiet (less than 75 dBA), easily set with a thermometer and holds the temperature setting. It’s ideal for applications where mist or liquid cooling can not be used due to part contamination or cost. Tolerances, product finish and production rates can improve dramatically.

The Adjustable Spot Cooler is available with either a single point or dual point hose kit. The single point system (Model 3825) is recommended for cooling a small surface like solder

joints, hot melts or drilled plastics. The dual point system (Model 3925) is recommended when heat is generated over a larger surface area.

Adjusting the Spot Cooler

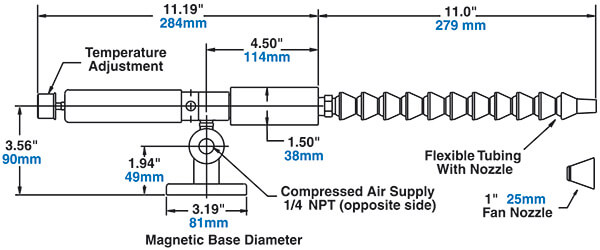

The Adjustable Spot Cooler System can produce a full range of airflows and temperatures as determined by the knob setting and a small internal part called a generator. The generators control the SCFM (SLPM) of air consumption and are easily interchangeable.

The Adjustable Spot Cooler has a 25 SCFM (708 SLPM) generator installed that produces up to 1,700 Btu/hr. (429 Kcal/hr.). If less cooling is desired, the 15 SCFM (425 SLPM) generator which delivers 1,000 Btu/hr. (252 Kcal/hr.) can be installed. If more cooling is needed, the

30 SCFM (850 SLPM) generator can be installed for up to 2,000 Btu/hr. (504 Kcal/hr.).

Controlling the Cold Air

The Adjustable Spot Cooler gives instant cold air when filtered compressed air is supplied to it. Cycling on and off is a good way to save air. For on and off control, use a Model 9012 Manual Shutoff Valve. To turn the Adjustable Spot Cooler on with the machine, Model 9020 Solenoid Valve may be used and wired through the machine control switch. EFC electronic flow control can also be used.

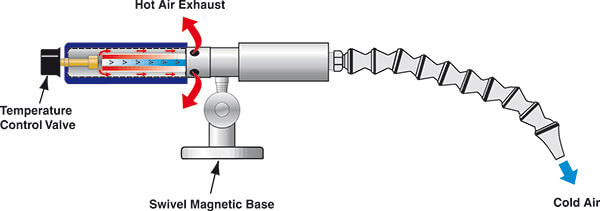

How the Adjustable Spot Cooler Works

The Adjustable Spot Cooler incorporates a vortex tube to convert an ordinary supply of compressed air into two low pressure streams, one hot and one cold. With the turn of a knob, the temperature control valve allows some hot air to flow through a muffling sleeve and out the hot air exhaust. The opposite end provides a cold airstream that is muffled and discharged through the flexible hose, which directs it to the point of use. The swivel magnetic base provides easy mounting and portability.