ATEX Cabinet Cooler® – approved for Zone 2 and Zone 22 areas

NEW: Switch cabinet cooler systems now also for hazardous areas in ATEX zones 2 and 22! Our switch cabinet coolers have now also received ATEX certification, which mainly applies to use in hazardous areas in the EU region!

What are control cabinet coolers?

Put an end to electronic control downtime due to heat, contaminants and moisture indoors or outdoors!

Control cabinet coolers for cooling dust- and oil-proof, splash-proof indoor and outdoor enclosures. One-way valves provide a liquid-tight seal when not in use.

- Deliver clean, cool air to electronic enclosures.

- Low-pressure valves maintain NEMA 4 integrity

- Constructed of aluminum and Type 303 stainless steel for long-lasting durability

What does Zone 2/Zone 22 mean?

The potentially explosive area does not exist during normal operation or only exists for a short time.

How do the conventional control cabinet coolers differ from the ATEX-certified systems?

EXAIR´s ATEX Cabinet Cooler Systems are control systems that are not purged and pressurized. Therefore they should not be relied upon neither used in place of a purged and pressurized controller. The cooler system is meant to be used in conjunction with a purged and pressurized control system!

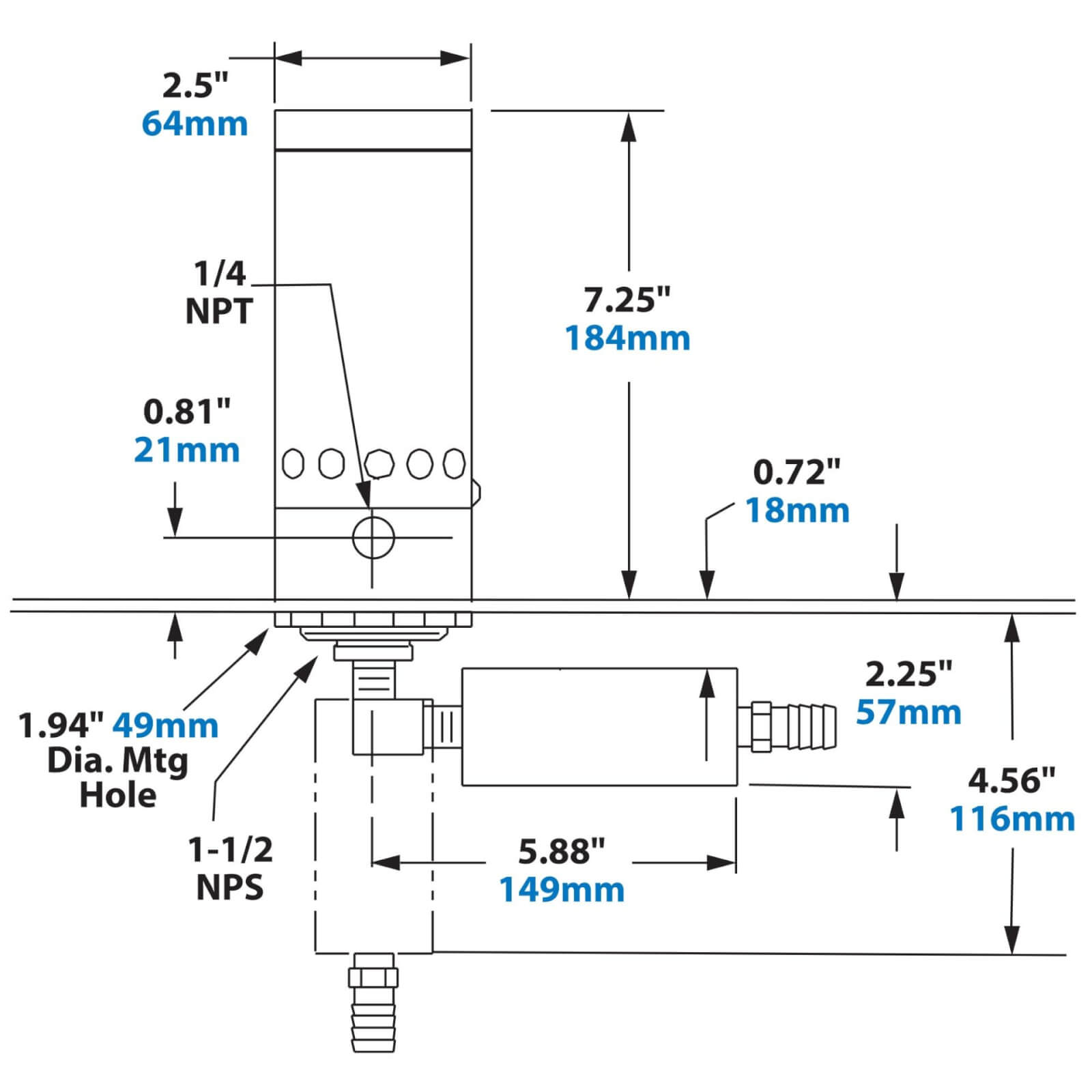

The maximum pressure of ATEX control panel coolers is 8.6 bar, the maximum inlet air temperature is 45 ° C, and cooling capacities range from 252 Kcal/h to 1,411 Kcal/h.

ATEX has various area classifications. These fall under the hazardous area standard. Here, three zones are covered in two hazardous areas: gas/liquid and dust. ATEX control cabinet coolers fall into Zone 2 for gas/liquid and Zone 22 for dust.

What are the advantages of EXAIR control cabinet coolers?

The Vortex vortex tube included in EXAIR cabinet coolers is made of stainless steel. Stainless steel’s resistance to wear, corrosion and oxidation ensures long life and maintenance-free operation.

The sizing guide form will help you pick the right control cabinet cooler model.

Calculate switch cabinet cooler here – selecting the right model or size.

We need the technical conditions at your site to be able to offer you the right control cabinet cooler.

EXAIR control cabinet coolers are available with or without thermostat. Continuous duty coolers are recommended when constant cooling and positive pressure are desired. A thermostatically controlled model saves air because the coolers are activated only when the temperature inside has reached a critical level. Thermostatic systems are useful when heat generation is variable and constant positive pressure is not required.

All EXAIR cabinet cooler systems include a 5 micron filter with automatic condensate drain for the compressed air supply and a hose kit to keep the cold air circulating inside the cabinet.

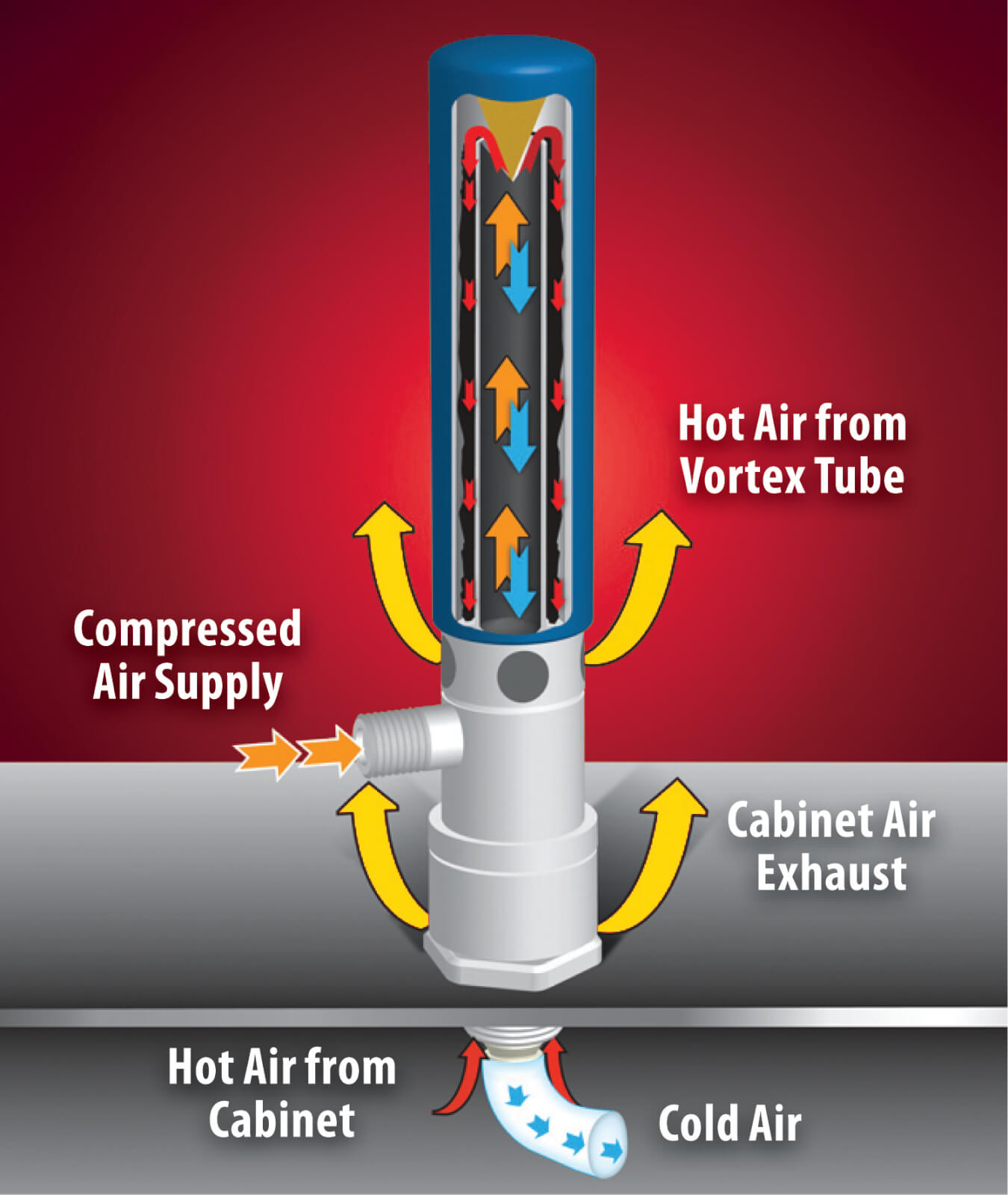

How do control cabinet coolers work?

Compressed air enters the vortex tube operated cabinet chiller and is split into two streams, one hot and one cold. (For more information on vortex tube operation, see the “Vortex Tubes” section). The hot air from the vortex tube is damped and exits the outlet. The cold air is expelled into the cabinet through the cold air distribution set. The displaced warm air in the cabinet rises and is discharged into the atmosphere through the cabinet air outlet at a slight positive pressure. In this way, the control panel is simultaneously cooled and purged with clean, cool air. No outside air can enter the control panel at any time.

Versions

Aluminum ATEX switch cabinet cooler systems

ATEX aluminum control cabinet coolers are suitable for use in flushed electrical enclosures in the appropriate approved areas. These areas are Zone 2 and Zone 22, and they meet both UL requirements and the stringent requirements of ATEX. Particularly suitable for cooling flushed electrical panels. Cooling capacities take place from 1,000 Btu/hr to 5,600 Btu/hr.

Easy installation ensured by standard electrical knockout.

Equipment: thermostat control or continuous operation system.

The ATEX aluminum switch cabinet coolers feature a low pressure relief valve. This closes and seals when the cooler is not in operation. This ensures integration of a NEMA 4 enclosure (dust and oil tight, splash proof, indoor/outdoor operation).

Each system includes a water-dirt filter separator (preventing dirt from entering the enclosure) and a cold air distribution kit (distributing air for circulation or redirection to hot spots).

All Cabinet Coolers are CE compliant.

The ATEX Cabinet Cooler systems are not purged and pressurized control systems. They are not a replacement for such a control system, but only in conjunction with such a system.

Stainless steel ATEX control cabinet cooler systems

ATEX stainless steel control cabinet coolers are suitable for use in flushed electrical enclosures in the appropriate approved areas. These areas are Zone 2 and Zone 22, meeting both UL requirements and the stringent requirements of ATEX. Particularly suitable for cooling flushed electrical panels. Cooling capacities take place from 1,000 Btu/hr to 5,600 Btu/hr.

Easy installation ensured by standard electrical knockout.

Equipment: thermostat control or continuous operation system.

ATEX stainless steel switch cabinet coolers feature a low pressure relief valve. This closes and seals when the cooler is not in operation. This ensures the integration of a NEMA 4 enclosure (dust and oil tight, splash proof, indoor/outdoor operation).

Each system includes a water-dirt filter separator (preventing dirt from entering the enclosure) and a cold air distribution kit (distributing air for circulation or redirection to hot spots).

All Cabinet Coolers are CE compliant.

The ATEX Cabinet Cooler systems are not purged and pressurized control systems. They are not a replacement for such a control system, but only in conjunction with such a system.