Cabinet Cooler® – NEMA 4X (IP66)

Cabinet Cooler constructed of stainless steel for food service!

The vortex tube in the EXAIR Cabinet Coolers are constructed of stainless steel. The wear, corrosion and oxidation resistance of stainless steel assures long life and maintenance free operation.

Cabinet Coolers maintain NEMA 4 are dust-tight, splash resistant and for indoor/outdoor service. NEMA 4 Cabinet Coolers incorporate a low pressure relief valve for both the vortex tube and the Cabinet Cooler exhaust. The valve closes and seals when the Cabinet Cooler ist not operating to maintain the NEMA 4 integrity of the NEMA 4 enclosure.

Why Exair Cabinet Coolers?

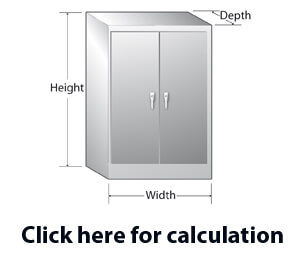

Selecting the right Cabinet Cooler. Please use our Cabinet Cooler Sizing Guide

Here Cabinet Cooler Sizing Guide – Select the right Cabinet Cooler

To determine the correct model for your application, it is necessary to determine your requirement.

EXAIR Cabinet Coolers are available with or without thermostat control. The continuous coolers (Model series 4200 and 4700) are recommended when constant cooling and a constant positive purge are desirable. When internal temperatures approach critical levels a thermostatically controlled systems (Model series 4300 and 4800) is ideal. A thermostatically system saves air by activating the cooler only when the internal temperature is critical.

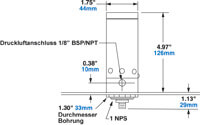

All Exair Cabinet Cooler Systems contain a 5 micron Automatic Drain Filter for the compressed air supply and a Cold Air Distribution Kit to circulate the cold air throughout the enclosure.

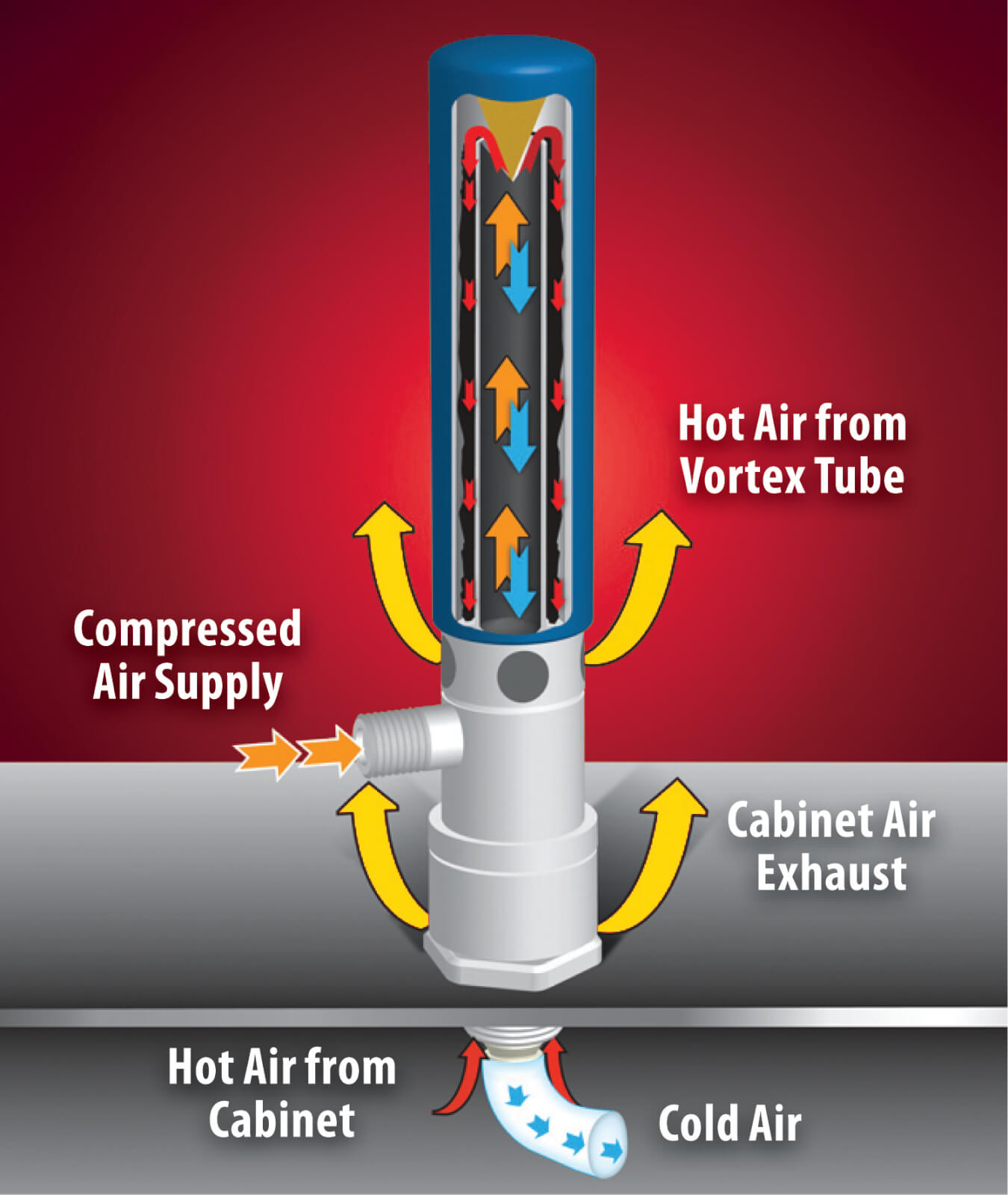

How The Cabinet Cooler Works

Compressed air enters the vortex tube powered Cabinet Cooler and is converted into two streams, one hot and one cold. (For more information on vortex tube operation, see Vortex Tubes. Hot air from the vortex tube is muffled and exhausted through the vortex tube exhaust. The cold air is discharged into the control cabinet through the cold air distribution kit. The displaced hot air in the cabinet rises and exhausts to atmosphere through the cabinet air exhaust at a slight positive pressure. Thus, the control cabinet is both cooled and purged with cool, clean air. Outside air is never allowed to enter the control panel.