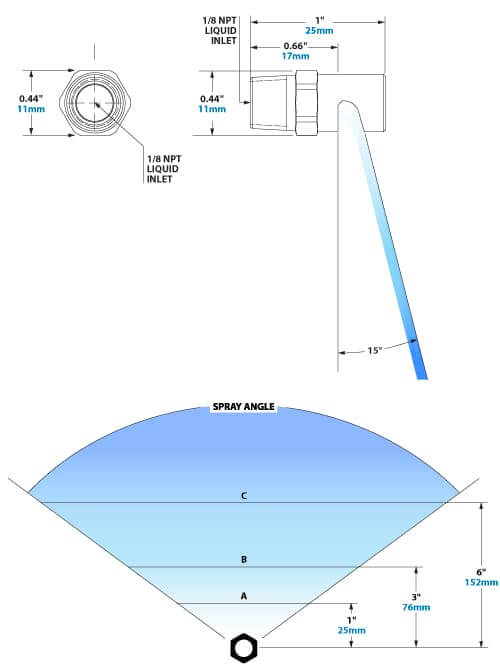

EXAIR PowerStream water nozzles produce a uniform, deflected flat fan spray pattern. This nozzle ensures efficient liquid distribution that is consistent across the full width of spray.

Its clog-resistant design makes it a perfect choice for environments dealing with particulates or potentially viscous fluids. This makes our PowerStream nozzles the perfect choice for environments where particles or potentially viscous liquids are handled, for example in industrial cooling, washing, rinsing, coating and dust suppression applications.

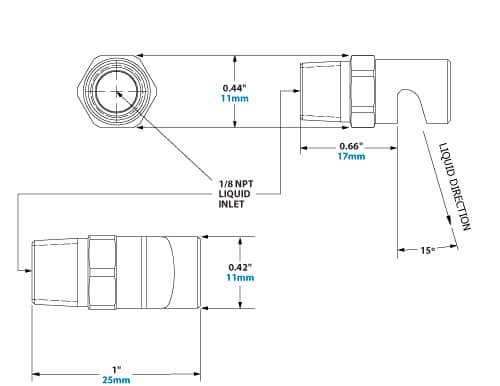

The PowerStream nozzles are constructed with Type 303 stainless steel, which can resist high temperatures and corrosive environments. They are designed for environments with a maximum operating temperature of 426°C. The nozzles are available with 1/8” BSP (NPT) thread in a wide range of flow rates and are suitable for use up to 17 bar liquid pressure.

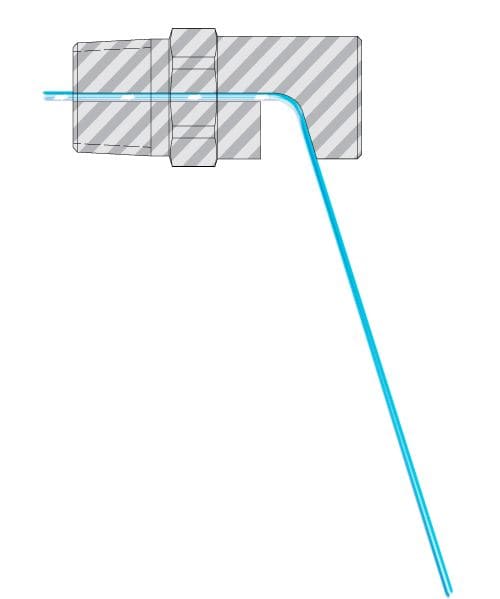

How the PowerStream works

With these nozzles, the atomizing fluid is supplied into the body of the nozzle where it is directed through the exit orifice, and deflected off the smooth, angled surface of the nozzle tip. The resultant spray shape is a wide-angle, deflected flat-fan pattern.

Applications:

- Cooling, coating

- Quenching

- Dust suppression

- Washing, rinsing

- Foam breaking

- Slurry spraying

- Sanitizing, degreasing

- Lubricating

Advantages:

- Solid, durable, one-piece construction

- Wide spray angle

- Clog-resistant

- All stainless steel construction

- Compact footprint, versatile