GEN4™ Super Ion Air Knife™ – Powerful static eliminator prevents jamming, tearing, shocks and dust up to 20 feet away!

What Is The GEN4™ Super Ion Air Knife?

GEN4 Super Ion Air Knife offers 34% improved performance and removes static electricity from plastics, webs, sheet stock and other product surfaces where tearing, jamming or hazardous shocks are a problem. The laminar sheet of air sweeps surfaces clean of static, particulate, dust and dirt. Production speeds, product quality, and surface cleanliness can improve dramatically.

Why The GEN4™ Super Ion Air Knife?

The GEN4 Super Ion Air Knife floods an area or surface with static eliminating ions – up to 20 feet (6.1m) away. A uniform airflow across its length will not cause misalignments to critical surfaces such as webs. Force can be adjusted from a “blast” to a “breeze”. The GEN4 Super Ion Air Knife is electrically powered, is shockless and has no moving parts. It also requires only 3.7 SCFM of compressed air per foot of length at 5 PSIG (105 SLPM per 300mm of length at 0.3 BAR). Sound level is surprisingly quiet at 50 dBA for most applications.

How the GEN4™ Super Ion Air Knife Works

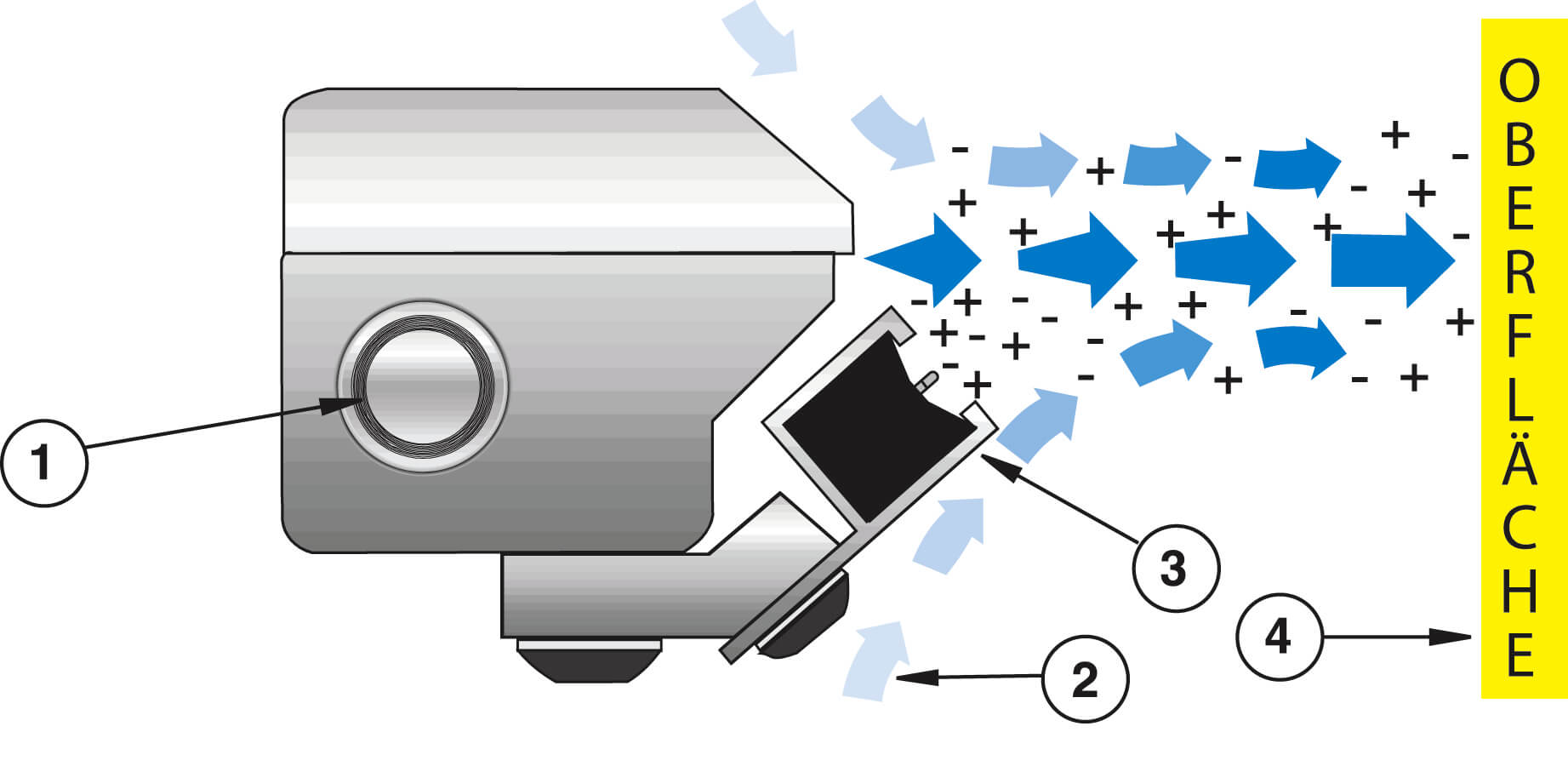

Compressed air flows through an inlet (1) into the plenum chamber of the GEN4 Super Ion Air Knife. The flow is directed to a precise, slotted orifice. As the primary airflow exits, it creates a uniform sheet of air across the entire length that immediately pulls in surrounding room air (2). An electrically powered GEN4 Ionizing Bar (3) fills the curtain of air with positive and negative charges. The airstream delivers these static eliminating ions to the product surface (4) where it instantly neutralizes static and cleans off dust and other particulates.

Enhanced Performance and Reliability

GEN4 Ionizing Bars are less effective without an air delivery system. When used by itself, a bar must be mounted within 4 inches of the charged surface to fully neutralize it. This close mounting is impossible when the static is generated in confined areas of a machine. Ion coverage is minimal on oddly configured parts or when high production speeds are involved.

The right type of air delivery is critical. Blowers produce an uneven, turbulent airstream that can cause the positive and negative ions to recombine before hitting the charged material. They are large, suffer mechanical wear and provide limited airflow control. The compact GEN4 Super Ion Air Knife uses a small amount of compressed air to produce a balanced, laminar sheet of air to carry the ions to the charged surface, even when it is far away. Flow and force are easily controlled and there are no moving parts to wear out.

Added Features

- Compressed air inlets (1/4″ NPT) are provided on each end and the bottom of the GEN4 Super Ion Air Knife. Multiple GEN4 Super Ion Air Knives can be mounted end-to-end without an air gap.

- Shims can be installed easily if additional hard-hitting velocity is required.

- Primary air does not impact any surface of the GEN4 Super Ion Air Knife which keeps the sound level low.

- Insertion molded emitter points eliminate potential dirt accumulation that could degrade performance or eventually short the ionizing bar.

- Emitter points are sharp, durable stainless steel.

- The power cable is shielded and has integral grounding. The threaded bayonet connector is fully assembled and ready to use.

- GEN4 Super Ion Air Knife Kits, which include all components necessary for operation, are available.

Universal Air Knife Mounting System

Provide precise positioning for your air knife

The Universal Air Knife Mounting System is used to provide secure, precise positioning for any of the EXAIR Air Knives. It can be mounted on either the top or bottom of most Air Knives (Super Air Knife, Standard Air Knife and Full-Flow Air Knife). The Universal Air Knife Mounting System has a durable, stainless steel construction that is suitable for a variety of industrial applications.

The mounting system can also be used with EXAIR GEN4 Static Eliminators. For the GEN4 Super Ion Air Knife, it can be mounted on the top. Bottom mounting is possible on GEN4 Super Ion Air Knives that are 18″ (457mm) or longer. For the GEN4 Standard Ion Air Knife, it can be top mounted on any length. Bottom mounting is possible on GEN4 Standard Ion Air Knives that are 9″ (229mm) or longer.

The Universal Air Knife Mounting System can be articulated into any position and provides a maximum extension of 30″ (762mm). A 17/32″ (14mm) diameter hole is required for mounting. Alternatively, the bolt can be threaded directly into a 1/2″-13 tapped hole. For any style air knife that is 24″ (610mm) or longer, it is recommended that (2) Universal Air Knife Mounting Systems be used to obtain a secure mounting.